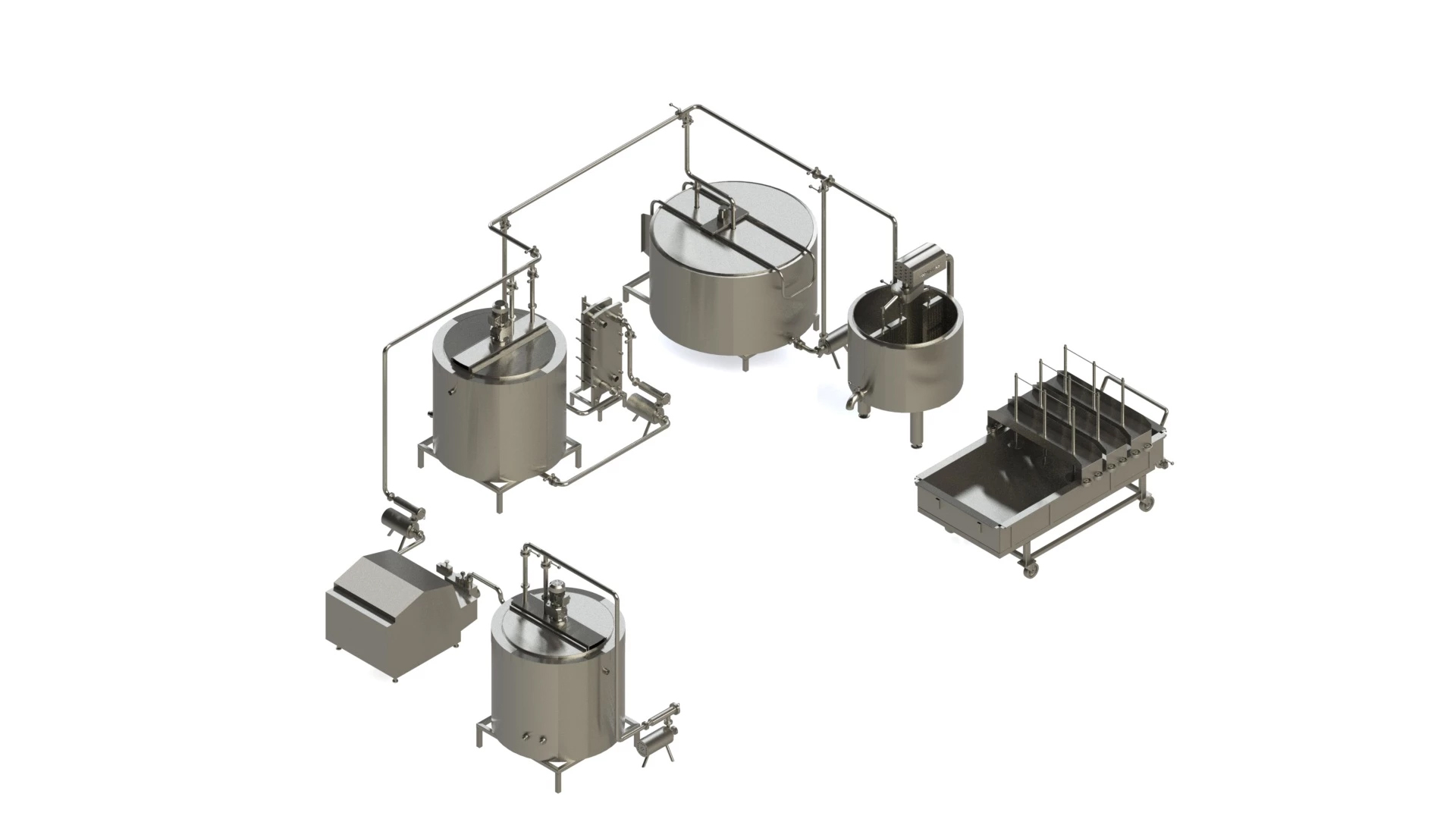

To thoroughly clean and sanitize dairy equipment and machinery, you will need a cleaning-in-place or “CIP” system. With a high degree of inaccessibility to the treatable areas, manual operations seem daunting.

Cleaning in place, or CIP, allows cleaning without dismantling, thus shortening the required time, besides using detergents and disinfectants at higher concentrations and temperatures, as well as the recovery of the cleaning solutions. The automation of these systems also allows for safe and reproducible results and economic optimization of the process.

Cleaning in place in Dairy Industry requires chemical, bacteriological, physical and sterile cleaning before the next production process forming an essential aspect of dairy production. Therefore, dairy machinery manufacturers recommend regular cleaning of equipment in between batches. CIP systems in dairy plants and other food and hygiene-focused industries are an efficient way to thoroughly clean and sanitize the interior of processing machinery and other equipment, creating a safer production space.

Proper cleaning (Cleaning-in-Place) and disinfection (Sterilization-in-Place) with specific chemicals prevent and break the disease cycle, decreasing the pathogen load. CIP systems have been designed for cleaning and disinfecting the interior processing machinery/equipment without the need for manual cleaning. Also, it requires a combination of a correct chemicals with a correctly configured CIP system to achieve optimal cleaning results in the shortest time possible. Clean in place is generally used in those industries where high levels of hygiene and thoroughly cleaning is needed.

Conventional CIP consists of Caustic Nitric Caustic (CNC) treatment followed by hot water sterilization, with significant amounts of energy and water being consumed in the process. Chemtex formulated CIP treatment is faster, less labour-intensive, more repeatable, and poses less chemical exposure risk.

The seven step CIP process for diary industry:

Mayuri CIP chemicals are uniquely formulated to enhance the performance of dairy plant equipment, and save money, water, and electricity as well with the following benefits:

Mayuri CIP formulations include a variety of active materials, including sequestering agents, stabilizers, etc that provide the best result for bacteria control and prevention in the dairy industry.

Other areas that can use CIP practices in dairy industry facilities include Plant conveyor systems to ensure clean and sanitized surfaces before the next production run, minimizing the chances of cross-contamination. Packaging Equipment where bacteria may cling and grow without proper cleaning. Refrigeration Systems essential to dairy processing plants. To ensure these large systems get thoroughly cleaned, a CIP system can help ensure that they are clean and sanitized.