Hydrotesting Corrosion Inhibitor has been specifically formulated in order to prevent corrosive attacks on Mild Steel and Carbon Steel (both low and high carbon) and in sea water rich with chloride ions. It provides excellent protection from corrosion to Metal Surface, Pipelines, Boilers, Vessels, Storage Tanks and other Industrial Equipment. Sea Water are being kept stagnant during Hydro Testing Applications which contains various microorganisms such as bacteria, fungi, algae, etc. and dissolved oxygen which generally accelerate metal corrosion. This formulation protects metal from oxidative corrosion and also functions as a bio dispersing agent.

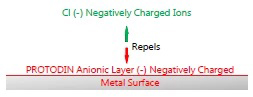

Hydrotesting Corrosion Inhibitor forms a passive layer on the metal surface with its anionic charge and in turn repels all negatively charged chlorine ions which would other wise form corrosive Hydrochloric Acid after reaction, causing heavy pitting and corrosion.

The Pipeline surface, generally made up of iron or steel, is positively charged and hence easily attracts negatively charged corrosion inhibitor over its surface.

Oxygen Scavenger

Dissolved oxygen in water corrode pipeline material by oxidizing it into its oxide. The catalyzed oxygen scavenger (cDEHA) rapidly reacts with dissolved oxygen, preventing oxidation reaction.

Reaction

cDEHA + Dissolved Oxygen = Vinegar + Nitrogen Gas + Water

The Vinegar formed post reaction, is relatively in small quantity and gets neutralized by sodium salt to form sodium acetate.

Hydrotesting Corrosion Inhibitor